Kundenspezifische Sensoren und Komponenten für OEM Anwendungen

Präzise, beständig, individuell optimierbar: OEM-Drucksensoren und Radarsensoren, angepasst nach Ihren Anforderungen und Ihrem Design

Unsere OEM-Sensoren

Differenzdrucksensoren

Silizium-Differenzdrucksensoren für vielfältige kundenspezifische Einsatzgebiete.

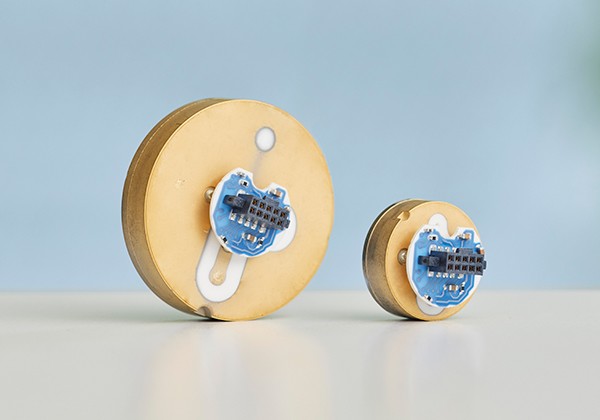

Absolut-/Relativdrucksensoren

Kundenspezifische Keramik-Drucksensoren zur Bestimmung von Absolutdruck bzw. Relativdruck.

Radarsensoren

Radarsensoren für den vielfältigen Einsatz in der Distanz- und Füllstandsmessung von Flüssig- und Feststoffen.

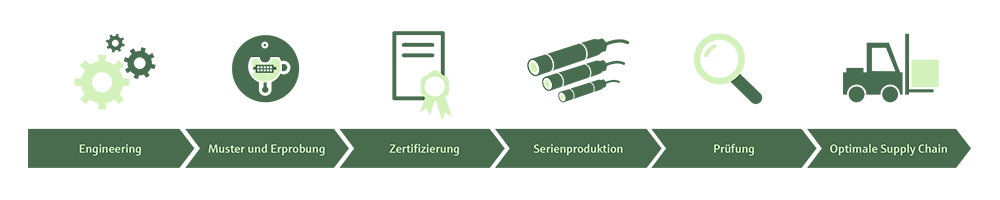

Know-how von der Produktidee bis zur Serienfertigung

Ob Engineering samt Prototypenfertigung, die Umsetzung eines Null-Fehler-Qualitätsziels in der Serienfertigung oder eine verlässliche Just-in-time-Lieferung: Mit unseren Services begleiten wir Sie entlang der gesamten Wertschöpfungskette. Individuell und anforderungsgerecht.